| Approach slabs | DOT Cement, Liquid Low-P™, Rapid Set® Cement |

| Back fill | Flowable Fill |

| Bridge deck overlays | Rapid Set® Latex-Modified Concrete, Komponent®, Liquid Low-P™, Low-P™ Cement, Low-P™ FA1 Cement, UHPC Mortar |

| Bridge decks | FPP Concrete Mix, Komponent®, Rapid Set® Cement |

| Closure pours (for precast elements) | DOT Concrete Mix, DOT Repair Mix, DOT Cement, Komponent®, Liquid Low-P™, Low-P™ Cement, UHPC Mortar |

| Footings | Komponent® |

| Grouting | Cement All®, Rapid Set® Cement, Komponent® |

| Hinge reconstruction | DOT Cement, FPP Concrete Mix, Liquid Low-P™, Rapid Set® Cement |

| Repairs and rehab | Concrete Mix, DOT Concrete Mix, DOT Repair Mix, FPP Concrete Mix, Liquid Low-P™, Mortar Mix, Mortar Mix Plus, UHPC Mortar, V/O Repair Mix |

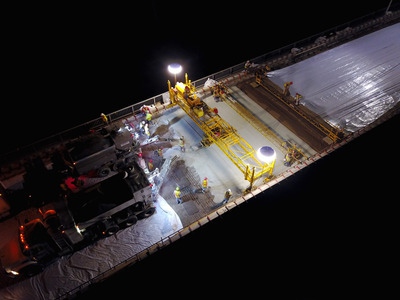

When working with very-early-strength Rapid Set® Concrete Mix, anything a crew can do to streamline processes gives them more time to optimize placement. Contractor HRI deployed multiple tactics to streamline partial-depth bridge deck replacement for the Pennsylvania DOT.

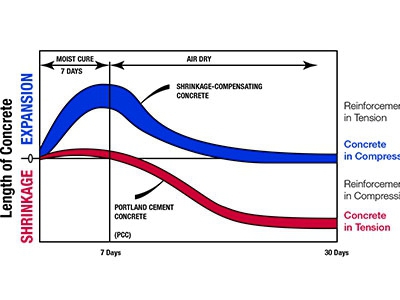

Four years after placing a concrete mix made with ASTM C845 expansive hydraulic cement, West Virginia adds Type K shrinkage-compensating concrete made with Komponent® expansive cement additive to its bridge deck specification.

Connecticut is making multiyear, multimillion-dollar repairs to a key transportation asset while developing a multiyear, multimillion-dollar plan to completely replace that asset. To maintain the driving public’s safety until construction on a new interchange begins, Walsh Construction is using Rapid Set® DOT Cement to patch reinforced concrete bridge decks.

More stringent performance requirements combined with changes in type, quality, and availability of concreting materials is inspiring innovation, creativity, and collaboration. It is also renewing interest in materials with established, proven performance that offer solutions to today’s challenges. One of those experiencing an inspiring renaissance is Type K cement.

Patching isn’t glamorous, but it must be done before placing an overlay to protect the reinforced concrete deck directly underneath. Because time is of the essence for bridge repairs, Connecticut used concrete made with Rapid Set® DOT Cement dispensed via a mobile volumetric mixer to partial-depth patch two lanes in two days.

Depending on mix design, latex-modified concrete (LMC) overlays made with portland cement can be reopened to traffic in 48 to 96 hours. To fast-track an overlay project on a bridge outside the state’s second largest city, PennDOT used a very-early-strength LMC (VESLMC) made with Rapid Set® cement instead. The overlay was ready for traffic after three hours.

Oregon usually specifies ultrahigh-performance concrete to fill precast panels in accelerated bridge construction projects. When the portland cement-based mix didn’t reach opening strength requirements, the state tried something new: ultrahigh-strength mortar made with calcium sulfoaluminate (CSA) cement. Rapid Set® UHPC Mortar provided twice the required strength requirement.

Rapid Set® Cement dosed with Liquid Low-P™ admixture gives public agencies a new option for very-low-permeability bridge deck overlays that can be quickly reopened to traffic. This is the one of several Oregon DOT projects using the mix.

The Mississippi DOT approved two things to fast-track a closure pour on a flyover near the state’s capital city: high-early-strength concrete made with ASTM C1600 very-rapid-hardening Rapid Set® Cement and concrete delivery via an onsite volumetric mixer.

The Holy Grail of concrete bridge deck maintenance is an easy-to-install, high-early-strength overlay for fast reopening and very low permeability for durability. North Carolina and Lanford Brothers try the latest option: Rapid Set® Cement dosed with Liquid Low-P™ (for “low permeability”) admixture.

The tire studs and chains that are popular with Pacific Northwest drivers carve troughs into concrete. A regional contractor and Washington State pavement engineers are watching how fast-setting, ultra high-strength Rapid Set® UHPC Mortar stands up to traffic.

HNTB – Kansas City, Mo., was selected to deliver Nebraska’s first design/build project: at 3,000 ft., one of the longest pedestrian bridges ever built. To ensure long-term durability through years of Midwestern seasonal changes, the firm chose Type K shrinkage-compensating grout made with Komponent® cement additive to fill the channels that house post-tensioned cables.

When a tall truck took out a Texas bridge, the state DOT wanted new concrete cross beams placed within 24 hours to minimize traffic disruption. The deadline was met because Hunter Industries used Rapid Set® Concrete Mix, Rapid Set® FLOW Control, and Rapid Set® SET Control to make the 10 concrete pedestals required to support the cross beams.

Quick return to service is critical to avoid disrupting traffic, especially if that traffic traverses a bridge. This state DOT used Rapid Set® Cement to replace concrete bridge deck expansion joints by 6:30 a.m. The material met the agency’s opening strength requirement of 4000 psi compressive strength in four hours.

Using a very-early-strength Rapid Set® product to meet opening strength requirements on overnight partial-depth bridge deck repairs was an easy decision for contractor Lee Carolinas -- especially because the material also meets South Carolina's other specifications.

All infrastructure must be repaired and restored as quickly as possible to minimize inconvenience to the traveling public. Caltrans facilitated the replacement of four hinges on a reinforced concrete box girder bridge by using Rapid Set® Cement concrete.

An East Coast city used Rapid Set® DOT Concrete Mix to rehabilitate a structural component rather than replace an entire bridge. SW Construction Enterprises used several techniques to promote concrete workability in temperatures ranging from below freezing to 90 degrees Fahrenheit.

When North Carolina decided to fully rehabilitate a four-lane bascule bridge built in 1980, PLC Construction used Rapid Set® DOT Concrete Mix to complete the work at night and have all bridge lanes opened to traffic on weekends and between 6 a.m. and 7 p.m. Mondays through Thursdays. The material met the state's compressive strength requirement of 4000 psi in 3 hours.

Time is of the essence when you’re rehabilitating infrastructure used by 40 million vehicles a year. The Port Authority of New York & New Jersey chose two Rapid Set® products because they eliminated the need for admixtures as well as met a tight opening strength requirement.

Maintenance crews from the Missouri DOT’s Northeast District sprang into action when drivers reported a large hole in a bridge deck one winter morning. By using Rapid Set® DOT Cement to repair the damage, the state was able to reopen the bridge to traffic the same day.

To prevent future shoving issues, Low-P FA1 Cement was used for the overlay. The work was completed in one weekend, and the result is a smooth riding surface that protects the underlying deck, providing long-lasting durability in Boston’s harsh freeze-thaw cycles.

Using Low-P FA1 Cement to place a new 6-inch-thick overlay on the bridge deck allowed the project to be completed in two days, resulting in minimal traffic disruptions. Passengers have an impermeable riding surface that provides corrosion resistance to the underlying deck reinforcement from road salts, providing long-lasting durability in Boston’s four-season climate.

DOT Repair Mix was used to repair the bridge joints on the Fremont Bridge. The repairs took place over different seasons where multiple weather conditions occurred. The bridge was able to reopen to traffic on time.

70,000 square feet of partial depth bridge deck repairs were performed with DOT Concrete Mix. Up to two lanes were closed at night and then reopened in the morning.

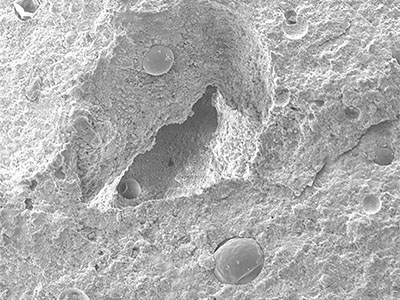

Unlike the chemically stabilized air bubble of traditional methods, Low-P MSA's air voids are made up of tiny, flexible hollow polymer spheres that act as microscopic forms in the cement matrix. They are rigid enough to form voids in the hardened concrete, yet soft enough to compress and allow space for expanding water to provide the desired freeze/thaw protection.

Fast-setting cement products were used for partial-depth repairs, repairing the lateral barriers, and anchoring and the new pipes for the new floor drains. Work took place in temperatures soaring above 90° degrees Fahrenheit. Products used were DOT Repair Mix, V/O Repair Mix, WunderFixx, Cement All, CR Concrete Resurfacer, and Corrosion Inhibitor.

Public agencies often fast-track bridge deck overlays by using Rapid Set® Cement in latex-modified concrete (LMC) mixes. In this case, Rapid Set® Latex-Modified Concrete (RSLMC) achieved a federal agency’s specified 2500 psi compressive strength requirement in 3 hours.

Low-P Cement was chosen as the repair material due to the short time allowed to reconstruct concrete portions of the bridge. Low-P Cement is very-rapid-hardening (VRH) per ASTM C1600 and reaches 4500 psi compressive strength in three hours. Work started at 8:00 am and both lanes were back in service by 6:00 pm.

Missouri’s largest bridge improvement project benefitted from fast-setting grout. The keyways were grouted with Cement All because it showed high early strength and excellent bonding characteristics during mock-up testing. The final evaluation of the bridge indicated that using a fast-setting, high-strength, nonshrink grout was a success. The bridge scored the highest possible NBI rating of 9-9-9.

The New Hampshire DOT was constructing a new bridge on I-93 in Concord and wanted a grout that would provide fast-setting strength and be easy to use. Product used was Cement All.

Several elements were in need of replacement or repair, including nearly 13,000 sq feet (1,200 sq meters) of patching for the 54-year-old concrete bridge deck. Because the bridge could not be shut down during repairs, a quick-set mortar was specified for the patching material. Product used was Cement All.

The specification called for a compressive strength of 3,000 psi prior to opening to traffic. The Rapid Set Latex-Modified Concrete overlay achieved this strength within three hours of placement, allowing the bridge to open for traffic each evening, meeting the DOT’s requirement. Product used was RSLMC.

Because of the high traffic volume on the Route 95 bridge, MassDOT developed a unique solution to complete deck repairs over the course of two weekends. Product used was Low-P cement.

The George Washington Bridge carries more than 106 million vehicles a year, making it the world’s busiest motor-vehicle bridge. The pothole-riddled north- and south-bound access ramps that connect the bridge to New York State Route 9A needed to be repaired. The Port Authority needed to reopen the busy ramps in a timely manner to not disrupt traffic patterns. Products used include Concrete Mix and DOT Cement.

The January 17, 1994, Northridge 6.6 earthquake did immense damage to many of the region’s vital traffic arteries. One serious disruption was the closing of the I-10 Santa Monica freeway due to the collapse of two bridges. The 1-10 is the busiest freeway in the nation. C.C. Myers completely rebuilt the two bridges 74 days ahead of schedule and received a $14.5 million bonus. Products used include Rapic Set Cement, Rapid Set Flowable Fill, and SET Control.

Drying shrinkage that followed the rebar on a bridge deck between two state highways caused a large hole to form. An overlay made with Komponent shrinkage-compensating concrete is protecting the newly reinforced deck from the overloaded trucks that regularly access it.

Today’s design, engineering, and construction professionals face a host of complex construction challenges. A vast majority of construction projects incorporate the use of concrete for its versatility, durability, and sustainability. This article discusses how Type K shrinkage-compensating cement improves the concrete by overcoming drying shrinkage cracking, reducing permeability, and improving sulfate resistance.

The cement used in concrete can have a lasting impact on the life span of new concrete bridge decks. Learn how Type K cement for new bridge construction and rapid hardening cement for repairs and new overlays can help extend the useful life cycle of concrete bridge decks.

Special cements allow for quicker, long-lasting concrete bridge and deck repairs.

After 20 years in service, six Type K cement bridge decks constructed in the early 1990s have proven their exceptional durability and crack mitigation performance. Shrinkage compensating concrete bridge decks are very low cost to maintain due to no deck delaminations, spalls or steel corrosion.

The I-280 bridge hinge joints are designed to slide and rotate, providing the 6-mile-long concrete structure the flexibility and stability to withstand an earthquake. The worn-out hinges on the bridge were replaced with hinges better designed to handle seismic forces. It was planned long before the Napa earthquake, which caused no damage to the structure. Product used was Rapid Set Cement.

In 1968, the State of Ohio began testing Type K concrete in bridge decks with impressive results. In 1984, the Ohio Turnpike Commission began a program of bridge deck replacement; since 1985, all deck replacements have been performed with Type K concrete. In the years since, other states, including Indiana, Michigan, Ohio, and Pennsylvania, have also adopted the use of Type K cement in bridge decks.

DOTs are tasked with deploying new techniques and new products to extend pavement in timeframes that reduce traffic interruptions and lane closure times. Rapid-hardening cement helps them meet this challenge, since it sets and gains strength rapidly. Products used include Cement All, Mortar Mix, FLOW Control, Low-P Cement, and Rapid Set Cement.

Rapid Set Latex-Modified Concrete (RSLMC) overlay helped move the Lewis & Clark Bridge project ahead of schedule and under budget. WSDOT saved a minimum of nine days by using RSLMC instead of a slower setting concrete overlay. The repairs will extend the life of the bridge another 25 years.

Wider use of proven technologies that eliminate or reduce concrete cracking in old or new decks can reduce the billions of dollars spent annually in the United States on repair or replacement of bridge decks damaged by chloride-induced corrosion. Products used include Type K shrinkage-compensating cement and RSLMC.