| Grout & precision grout | Cement All®, Komponent®, Type K Cement |

| Repairs and rehab | Concrete Mix, DOT Concrete Mix, DOT Repair Mix, FPP Concrete Mix, Liquid Low-P™, Mortar Mix, Mortar Mix Plus, UHPC Mortar, V/O Repair Mix |

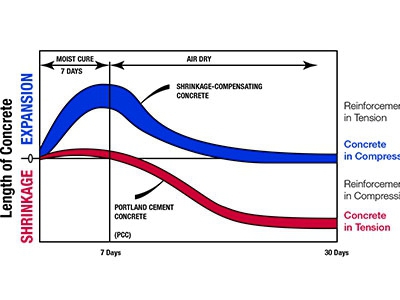

| Shrinkage-compensated concrete | Komponent®, System-K™ |

| Topping slabs | Concrete Mix, Komponent®, System-K™, DOT Repair Mix |

The ability to place large, concrete monolithic structures without contraction joints, construction seams, or shrinkage cracks makes shrinkage-compensating concrete an ideal choice.

The slabs were placed in a new facility, two sections per day, at a size of 10,000 to 12,000 sq. ft. No control joints were used. The product used was Komponent.

The global no-frills grocery store has built numerous warehouses using Type K concrete made with Komponent shrinkage-compensating cement additive. In this facility, using Komponent enabled joints to be extended to 110 ft. x 110 ft. (33.5m x 33.5m) to align with column spacing and maximize installation efficiencies.

Extended joint spacing up to 165 ft. 6 in. (50.4m) in the main marshaling area and receiving areas were achieved using Type K shrinkage-compensating concrete with integral steel fiber reinforcement and Cosinus Slide armor joints.

The concrete slab replacement was done quickly and during off-hours to not disrupt operations at the food-waste recycling plant. Low-P FA1 Cement was used and the floor was return back to service within hours.

By using Type-K shrinkage-compensating concrete, 85% of joints were eliminated over 200,000 linear feet. Slabs were placed in 10,000-to-15,000-square-foot blocks; the only joints were construction joints 100 to 120 feet apart. Curling was eliminated at those joints, drastically reducing Lowe's forklift and floor maintenance.

Toyota's Facilities Project Manager noted, "We felt that we optimized the value of the dollars we spent on our warehouse" using Type K Shrinkage-Compensating Concrete. Upon evaluation of savings in concrete maintenance alone, the facilities team reported an annual savings of over $10,000 using Type K Shrinkage-Compensating Concrete when compared to their other parts-warehousing locations.

S+S Concrete Floors worked with Redi-Mix Companies and our Komponent team to develop a shrinkage-compensating Type K concrete mix design that would allow placement of 40,000-sq.-ft. slabs without a single control joint. With forklifts getting heavier, the project owner will benefit via lower maintenance repair costs.

Conventional floors have a lot of joints and can curl and crack, but a System-K shrinkage-compensating concrete floor doesn’t have those problems. Product used was System-K.

Sugar Creek was very pleased to have a high performance floor with minimal construction and control joints and no drying shrinkage cracking. This gave them peace of mind for maintaining efficient facility operations and significantly reducing maintenance costs for both the floors and transfer equipment (e.g., forklifts, carts) throughout the facility. Product used was System-K.

There are virtually no cracks in more than 420,000 ft2 (39,000 m2) of slab. Further, the concrete frame was bid and constructed under budget and completed 42 days ahead of schedule. Because the slab was originally bid with pour strips and then re-bid with

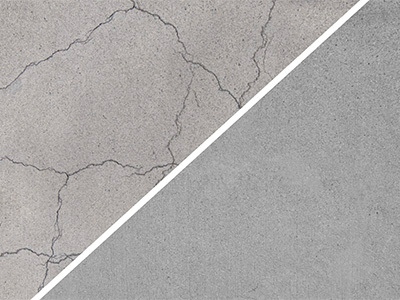

Today’s design, engineering, and construction professionals face a host of complex construction challenges. A vast majority of construction projects incorporate the use of concrete for its versatility, durability, and sustainability. This article discusses how Type K shrinkage-compensating cement improves the concrete by overcoming drying shrinkage cracking, reducing permeability, and improving sulfate resistance.

This 110 ft x 130 ft slab does not have steel reinforcment and has a FF (floor flatness) of 98.6. Product used was System-K shrinkage-compensating fiber reinforced concrete.

Contractor installs a high performance floor with minimal construction and control joints in large food processing facility. Product used was System-K shrinkage-compensating fiber reinforced concrete.

Specified by consulting engineering firm Crawford Murphy & Tilly (CMT), Type K shrinkage-compensating concrete was used for the Springfield Wastewater Treatment Facility Expansion in Springfield, Illinois, USA to mitigate shrinkage-related cracks.

Type K negates the stresses induced by shrinkage, it can prevent cracks, achieving a jointless floor that performs better and saves money for building owners over a long service life. Product used was Type K shrinkage compensating cement.

This article shares some unique features of the Gatorade facility’s floors, which are significantly different from typical bottling or warehouse facility floors. The final design of the floors specified over 415,000 ft. (38,000 m2), most of which were of shrinkage-compensating concrete. Product used was Type K shrinkage-compensating cement.

Precision is a must, not an option, on the manufacturer's military aviation production line. To provide the monolithic, super-flat floor slab required to install and operate a large and heavy friction stir welder, 15% of the portland cement in the concrete mix design was replaced with Komponent shrinkage-compensating cement additive.

The outcome of using the shrinkage-compensating cement was a 102x206-ft. crack-free slab with a dense and durable surface. Product used was Komponent.

This industrial slab was designed to reduce floor joints and cracks. The owner’s receptiveness to innovation and high expectations translated into a finished industrial slab that is flat and durable at the center of the slab and at the joints. These innovative products and attention to detail reduces future maintenance and repair costs for the slabs and equipment they carry for the life of the distribution facility. Product used was Type K shrinkage-compensating cement.