| Grouting | Cement All®, Rapid Set® Cement, Komponent® |

More stringent performance requirements combined with changes in type, quality, and availability of concreting materials is inspiring innovation, creativity, and collaboration. It is also renewing interest in materials with established, proven performance that offer solutions to today’s challenges. One of those experiencing an inspiring renaissance is Type K cement.

HNTB – Kansas City, Mo., was selected to deliver Nebraska’s first design/build project: at 3,000 ft., one of the longest pedestrian bridges ever built. To ensure long-term durability through years of Midwestern seasonal changes, the firm chose Type K shrinkage-compensating grout made with Komponent® cement additive to fill the channels that house post-tensioned cables.

CSA cement is a proven technology for the underground construction industry. The fast set time, high strength, low porosity, high chemical stability and sulfate resistance make it a material uniquely suited for underground repairs, shotcrete and other applications as needed.

A non-shrink grout was required to secure the piles to avoid voids that might absorb water in the nail tubes and cause corrosion of the steel. Shrinkage-compensating Type K grout was specified to meet these needs and mixed in ready-mix trucks for the 366-ft.-by-50-ft. project area.

Six curved and submerged stainless steel gates are helping control water releases from a new spillway. A 7000-psi non-shrink grout made with Komponent shrinkage-compensating cement additive is ensuring a durable, watertight seal.

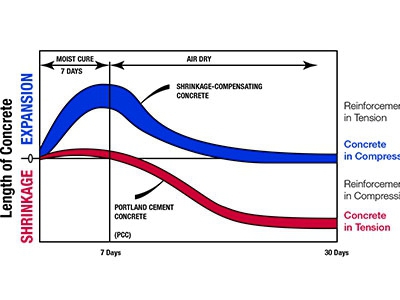

Today’s design, engineering, and construction professionals face a host of complex construction challenges. A vast majority of construction projects incorporate the use of concrete for its versatility, durability, and sustainability. This article discusses how Type K shrinkage-compensating cement improves the concrete by overcoming drying shrinkage cracking, reducing permeability, and improving sulfate resistance.