| Grouting | Cement All®, Rapid Set® Cement, Komponent® |

| Repairs and rehab | Concrete Mix, DOT Concrete Mix, DOT Repair Mix, FPP Concrete Mix, Liquid Low-P™, Mortar Mix, Mortar Mix Plus, UHPC Mortar, V/O Repair Mix |

| Reservoirs | Komponent® |

| Secondary containment (concrete basin) | Komponent®, System-K™ |

| Storage & facilities | Komponent®, System-K™ |

| Tanks (wet and dry, horizontal) | Komponent®, System-K™ |

| Tanks (wet and dry, vertical) | Komponent® |

| Topping slabs | Concrete Mix, Komponent®, System-K™, DOT Repair Mix |

| Waterstop Repair | Water Stop |

More stringent performance requirements combined with changes in type, quality, and availability of concreting materials is inspiring innovation, creativity, and collaboration. It is also renewing interest in materials with established, proven performance that offer solutions to today’s challenges. One of those experiencing an inspiring renaissance is Type K cement.

Engineer and contractor Structural Engineering Group (SEG) specified System-K – a blend of Komponent® shrinkage-compensating cement additive, K-Fiber™, and locally sourced portland cement – to replace eight concrete caps at the Jennings Randolph Lake dam.

Downhole Products chose Rapid Set Cement for their wellhead caps. Using Rapid Set Cement helped the crew meet specifications of 3,500 psi in 24 hours.

The concepts used to construct leak-proof tank farms can be adapted to other containment structures, such as truck loading/unloading stations, railroad loading and unloading stations, drum filling operations, and other areas where leaks or drippages are likely to occur. These environmentally safe state-of-the-art containment structures can be constructed due to the special characteristics of shrinkage compensating concrete made with Type K cement.

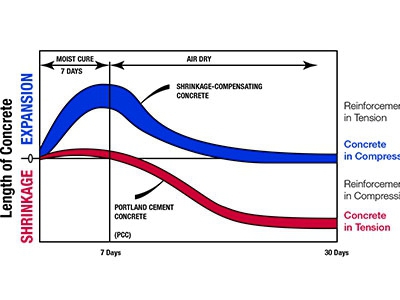

Today’s design, engineering, and construction professionals face a host of complex construction challenges. A vast majority of construction projects incorporate the use of concrete for its versatility, durability, and sustainability. This article discusses how Type K shrinkage-compensating cement improves the concrete by overcoming drying shrinkage cracking, reducing permeability, and improving sulfate resistance.

More than ten years later the Roberto R. Bustamante Waste Water Treatment Plant (WWTP) and the Jonathon W. Rogers Water Treatment Plant (WTP) are still crack free and leak free. Product used was Type K shrinkage-compensating cement.