Built in 1980, the four-lane Isabel Holmes Bridge crosses the Northeast Cape Fear River in downtown Wilmington, N.C., and has made appearances on the big screen (“Maximum Overdrive” and “Cat’s Eye”). By 2019, the bascule bridge was in poor condition due to wear and tear. To avoid having to completely replace the drawbridge, the North Carolina DOT (NCDOT) decided to perform a full rehabilitation—from top to bottom.

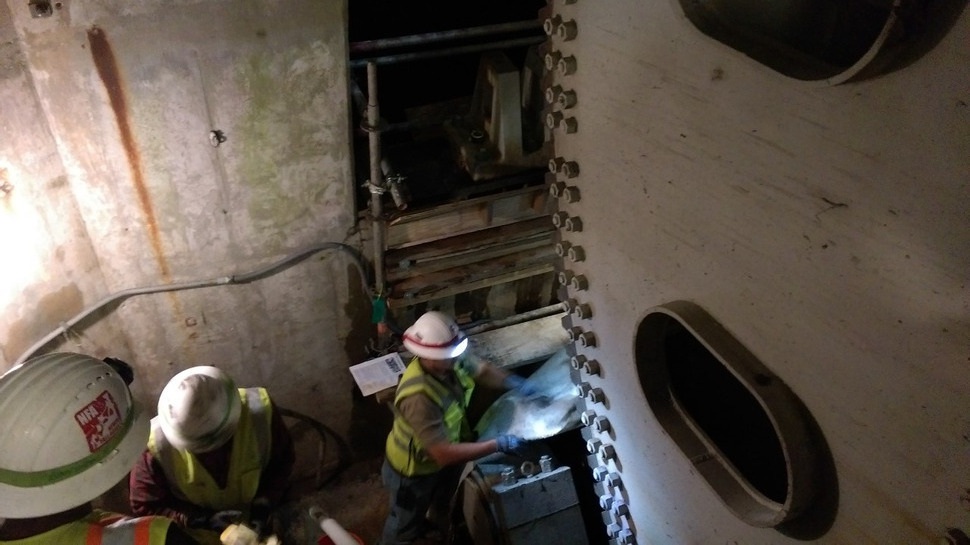

NCDOT awarded the bridge preservation project to PCL Construction. As part of the project, the contractor had to remove and replace the concrete surrounding the hinges and anchor the bearing plates that support the drawbridge when it is in the down position. This is the superstructure of the bridge the public never sees, but it is vital to the bridge’s safety and performance. The bridge had to remain in the up position for the repair work to be performed.

What’s more, NCDOT required all bridge lanes remain open to traffic on weekends and between 6 a.m. and 7 p.m. Mondays through Thursdays. This meant the work had to be performed overnight during the week, with the contractor facing late-opening penalties of $2,000 for every 15 minutes lanes remained closed.

To keep within time constraints and meet a compressive strength requirement of 4000 psi within 3 hours, PCL used Rapid Set® DOT Concrete Mix.

Formulated for long life in critical applications, DOT Concrete Mix is a blend of Rapid Set® Cement, high-performance additives, fibers and quality ASTM C33 3/8-inch aggregates. The polymer-modified concrete repair material is corrosion-resistant and fast-setting—ready for traffic and loading in 2 hours.

When the bridge is down, it rests on bearing pads, which are steel plates with anchor bolts embedded in concrete to hold the plates in place. The concrete had deteriorated over the years under the heavy loads it supported, as well as the concrete surface extending out 15 feet to 20 feet from the bridge hinges. After cutting up and removing the old concrete, the PCL crew mixed DOT Concrete Mix in

5-gallon buckets using a paddle mixer and hoisted the buckets to the repair area for forming and placement. They finished the repaired areas with hand trowels and covered them with wet burlap for curing.

The repair work began October 2019 and was completed a month later. Using Rapid Set DOT Concrete Mix allowed the contractor to lower the bridge and open it in time for morning traffic after each night of work. Both PCL and NCDOT were pleased with the overall performance of the fast-setting concrete repair material.