Built in 1980, the three-lane bridge that carries Route 60 over a creek at the intersection of three Pittsburgh boroughs is just one of Pennsylvania’s 25,000 state-owned bridges. But because it’s on the outskirts of the state’s second largest city, the Thornburg Bridge is a key asset in the state’s transportation network. With an average of 18,064 vehicles crossing the bridge daily – and a sidewalk for pedestrians – closing the structure for repairs would be a major public inconvenience.

Updating the bridge was one of hundreds of projects covered by $1.04 billion in federal, state, and local funding that Pennsylvania allocated for transportation improvements in 2021. Beginning the following year, traffic signals were replaced, Americans with Disabilities Act (ADA) curb ramps were installed, guide rails were updated, and the 40-year-old reinforced concrete deck was restored and preserved with a latex-modified concrete (LMC) overlay.

The Pennsylvania DOT (PennDOT) kept at least one lane of traffic open through most of the work but anticipated two weekend full closures would be required to install the overlay. Instead, it was installed in one full closure.

That’s because the state used an LMC overlay mix made with ASTM C1600 very-rapid-hardening Rapid Set® calcium sulfoaluminate (CSA) cement instead of ASTM C150 Type III portland cement. The latter, typically referred to as a high-early-strength (HES) LMC mix, must be cured for 48 hours after placement. A Rapid Set® Latex-Modified Concrete (RSLMC) overlay meets the ACI 548 Section 3.3 requirement that a very-early-strength (VES) LMC reach a minimum 2500 psi compressive strength at three hours – including curing time. No accelerators are required.

Everything’s (Almost) the Same

A Rapid Set® LMC is installed using the same tools, equipment, and processes used to install an LMC made with portland cement.

The surface of the Thornburg Bridge was prepared by removing ½ inch of the deck via scarification followed by a hydrodemolition robot programmed to remove at least an additional ¾ inch. The surface was hosed down and the slurry was vacuumed up. The clean surface was then covered with polyethylene reflective sheeting to keep it clean.

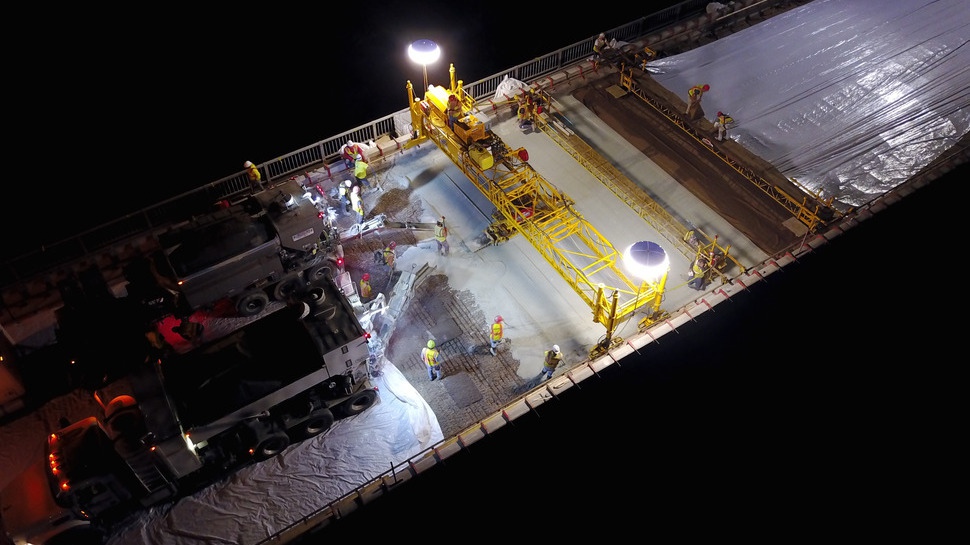

The bridge was closed to traffic at 9 p.m. Friday to begin installation of the overlay. Because of the overlay’s very early strength and short curing time, crews were able to texturize the surface via longitudinal grooving before the bridge was reopened to traffic 6 p.m. Sunday. Reopening was originally scheduled for 6 a.m. Monday.

Of the 19 months the entire $3.15 million Thornburg Bridge Preservation Project took to complete, placing and finishing the overlay took just one weekend. Before restoration, PennDOT rated the deck as in “fair” condition; after, as “very good.”