Oklahoma City concrete flooring specialists Thomas and Josh Owens used six Rapid Set® products to repair and finish 22,000 square feet of cracked and uneven slab – Owens Concrete Staining’s largest installation of TRU® SP polished concrete topping.

This South Korean cold storage facility was no exception to the rule that warehouse floors take a beating. Starcon International used Rapid Set® Cement All® all-purpose repair material as the underlayment for a Rapid Set TRU® Self-Leveling polished concrete overlay.

Mortar Mix was used to repair spalling and bug holes. Cement All was used to fill spalls larger than ½ inch and fastener holes left behind by drilled-in formwork. WunderFixx was used for cosmetic pinhole repairs and to coat larger areas for a smooth appearance.

It is possible to reduce panel thickness by 20%, eliminate 70% or more of traditional rebar, and erect panels the same day they are poured. Products used include Cement All, WunderFixx, Rapid Set Cement and FastRock TU.

Copings at train station were repaired to provide a safe surface for embarking/disembarking passengers. Work was performed during hot weather with temperatures reaching 95 degrees Fahrenheit. Cement All and SET Control were used.

Extensive new flooring was installed in the interior. To accommodate the flooring, Cement All was used to raise the concrete pads. SET Control was used to increase the working time, allowing more time for placement and finishing.

The Rapid Set products met Arizona's specifications and standards. Workers did more work in a shorter amount of time due to the fast cure time and saved on labor costs. Cement All, Mortar Mix, Mortar Mix Plus and WunderFixx were used.

During the store remodel, workers had to perform extensive surface prep prior to the TRU installation. Cement All was used for the repairs and TRU Self-Leveling with integral colors were used as the polished concrete overay. The final surface was polished to an 800 grit and sealed.

Cement All, Concrete Mix and LevelFlor were used to restore the existing floors and create a smooth surface. TXP Fast Epoxy Primer, TRU Self-Leveling, and TRU Self-Leveling Spiked Rollers were used to create the polished concrete overlay.

Acrylic Primer, Cement All, Concrete Resurfacer, LevelFlor, SET Control and WunderFixx were used in various areas of the completed facility to mitigate standing water and create sanitary, level surfaces.

The shower drains were too flat and not draining properly. Cement All was applied after chipping around the drain to create a slope. It was chosen because of its high bond properties and ability to be applied at a thin application.

Cement All and Mortar Mix were used for structural repairs on the 850,000-square-foot beverage manufacturing and distribution hub. WunderFixx was then used to smooth the surfacers before paint was applied.

The floors of Gucci's offices and showroom were renovated by first leveling the surface, then installing a polished concrete overlay. Rapid Set® Acrylic Primer, Cement All®, LevelFlor®, TRU® PC Polished Concrete, and TRU® PC Spike Roller were used.

Fast-setting cement products were used for partial-depth repairs, repairing the lateral barriers, and anchoring and the new pipes for the new floor drains. Work took place in temperatures soaring above 90° degrees Fahrenheit. Products used were DOT Repair Mix, V/O Repair Mix, WunderFixx, Cement All, CR Concrete Resurfacer, and Corrosion Inhibitor.

The Colorado Tower opened as Austin, Texas’ first high rise in 10 years. In the construction of the 2 outdoor patios Rapid Set Cement All and Mortar Mix was used to meet the specifications that called for high-bond and early strength upon the waterproofing membrane.

Cement All was used to patch the substrate before performing surface prep. To prevent pinholes and create a strong adhesive grip for the topping, TXP Fast Epoxy Primer was used. TRU Self-Leveling with integral coloring was used as the topping. To make sure the TRU did not set too fast in the heat, SET Control was added to the mix.

Blue C Sushi wanted an integrally colored black polished concrete floor in their new restaurant. Cement All was used to patch the substrate before performing surface prep. TXP Fast Epoxy Primer was used to prevent pinholes and create a strong adhesive grip for the topping. Then TRU Self-Leveling with black integral color was placed at 3/8 inch thick.

The slab on three of the four floors of this new structure was either pocked with formwork-related imperfections and/or not the proper elevation. The repair specifications required a fast-setting, high-strength material, so the contractor used Rapid Set® Cement All® for thicknesses up to 4 inches and Rapid Set® Mortar Mix for thicker applications.

All cement and concrete products used in this project had to meet State of Arizona specifications and requirements. Cement All, Mortar Mix and Mortar Mix Plus were used for horizontal and vertical repairs. WunderFixx was used to smooth out the repaired surfaces. Because temperatures ranged from 108° to 120°F, the crew used hot-weather concrete techniques.

Several elements were in need of replacement or repair, including nearly 13,000 sq feet (1,200 sq meters) of patching for the 54-year-old concrete bridge deck. Because the bridge could not be shut down during repairs, a quick-set mortar was specified for the patching material. Product used was Cement All.

Part of the $20 million renovation project at The Outlets at Montehiedra was to resurface the entire 14,000 square feet of the property’s 25-year old concrete sidewalk. Products used were Acrylic Primer, Cement All, and CR Concrete Resurfacer.

The New Hampshire DOT was constructing a new bridge on I-93 in Concord and wanted a grout that would provide fast-setting strength and be easy to use. Product used was Cement All.

The campus parking structure was in dire need of structural repairs. The property owner wanted a permanent, durable solution that could withstand the corrosive seaside environment and be installed quickly within five months. Products used include Cement All, Mortar Mix, V/O Repair Mix, and WunderFixx.

Approximately 800 square feet of slab needed to be repaired, with the majority of repairs taking place on the ramp at the entrance to the garage. Because the building was still under construction, the crew had to work around heavy forklift traffic and needed a fast-setting cement material for the work. Product used was Cement All.

The concrete subsurface was in dismal condition, with extensive craters and divots throughout. Contractors had to bring these numerous voids level to the adjacent concrete surface. Products used include Cement All, Concrete Mix, and LevelFlor.

Leveraging the precision and freedom of industrial robots to design a new concrete casting method using Cement All.

DOTs are tasked with deploying new techniques and new products to extend pavement in timeframes that reduce traffic interruptions and lane closure times. Rapid-hardening cement helps them meet this challenge, since it sets and gains strength rapidly. Products used include Cement All, Mortar Mix, FLOW Control, Low-P Cement, and Rapid Set Cement.

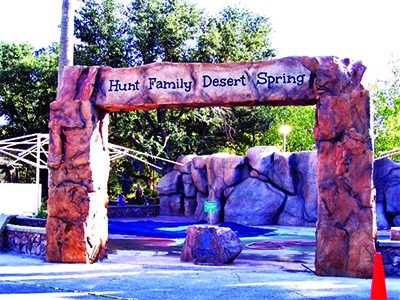

Approximately 600 square feet of rock-like concrete blends in with the zoo's natural settings. With less than two weeks to create the 14-ft-tall x 20-ft-wide x 4-ft-deep precast concrete entrance, Aquamatic Landscape was able to complete the project on time. Product used was Cement All.

Five international projects show how construction products play a supporting role in industries where new technology rollouts, tight timelines, and sustainable design are the new normal. Products used include Cement All, Concrete Mix, Rapid Set Cement, SET Control, and TRU Self-Leveling.