Oklahoma City concrete flooring specialists Thomas and Josh Owens used six Rapid Set® products to repair and finish 22,000 square feet of cracked and uneven slab – Owens Concrete Staining’s largest installation of TRU® SP polished concrete topping.

Remodeling at the corporate office of the world’s largest bank provides a textbook example of why project owners and contractors choose Rapid Set® self-leveling polishable overlays: fast turnaround and a beautiful aesthetic. Award-winning commercial flooring contractor RD Weis installed this TRU® SP floor in less than a week.

Contractors often face challenges when asked to produce a uniform appearance in a polished concrete overlay. To achieve consistency in each project, here are the three necessary steps to take before grinding and polishing.

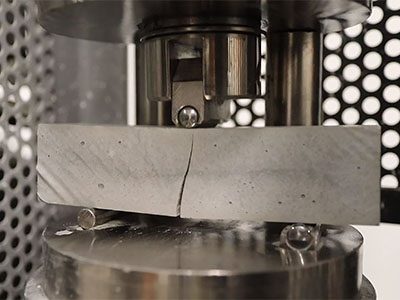

To ensure decorative overlayments achieve performance and aesthetic expectations, compressive, tensile and flexural strengths must be evaluated as a whole. Together, they provide a more comprehensive analysis of overall performance. This approach help architects and specifiers meet and exceed performance and aesthetic expectations in polished overlay designs.

After renowned architect Norman Foster was asked to lead the expansion and renovation of the famed Norton Museum of Art in West Palm, he wanted a high quality seamless concrete floor. Because of the excellent results Kemiko Concrete System achieved with Rapid Set TXP Fast, LevelFlor, and TRU SP, they received an award of excellence from the museum owner.

Thin coatings that can be polished work wonders on floors new and old. But applying them right takes know-how.

One of many reasons polished concrete toppings are popular as a finished floor system for both damaged floors and new construction is customers want polished concrete without all the flaws showing up in the finished floor. Placing and polishing a concrete overlay requires a great deal of attention and more coordination than polishing an existing slab. Here are a few tips when taking on an overlay-polishing job.