Time is of the essence when you’re rehabilitating infrastructure used by 40 million vehicles a year. The Port Authority of New York & New Jersey chose two Rapid Set® products because they eliminated the need for admixtures as well as met a tight opening strength requirement.

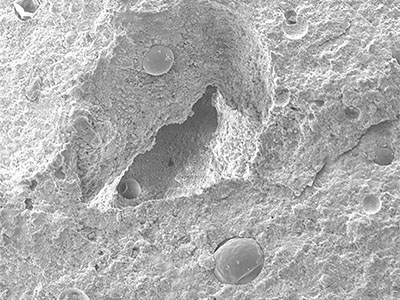

Unlike the chemically stabilized air bubble of traditional methods, Low-P MSA's air voids are made up of tiny, flexible hollow polymer spheres that act as microscopic forms in the cement matrix. They are rigid enough to form voids in the hardened concrete, yet soft enough to compress and allow space for expanding water to provide the desired freeze/thaw protection.

Low-P Cement was chosen as the repair material due to the short time allowed to reconstruct concrete portions of the bridge. Low-P Cement is very-rapid-hardening (VRH) per ASTM C1600 and reaches 4500 psi compressive strength in three hours. Work started at 8:00 am and both lanes were back in service by 6:00 pm.

Because of the high traffic volume on the Route 95 bridge, MassDOT developed a unique solution to complete deck repairs over the course of two weekends. Product used was Low-P cement.

DOTs are tasked with deploying new techniques and new products to extend pavement in timeframes that reduce traffic interruptions and lane closure times. Rapid-hardening cement helps them meet this challenge, since it sets and gains strength rapidly. Products used include Cement All, Mortar Mix, FLOW Control, Low-P Cement, and Rapid Set Cement.