In a previous blog, I discussed the U.S. General Services Administration (GSA) table that defines low-embodied-carbon (LEC) concrete. Since then, the agency has published a new draft document updating the table and adding a definition for LEC cement.

The GSA’s first global warming potential (GWP) limits were broken into three categories by concrete mix type: standard, high-early, and lightweight strength. Based in part on industry feedback, the agency now categorizes mixes relative to the industry-average GWP.

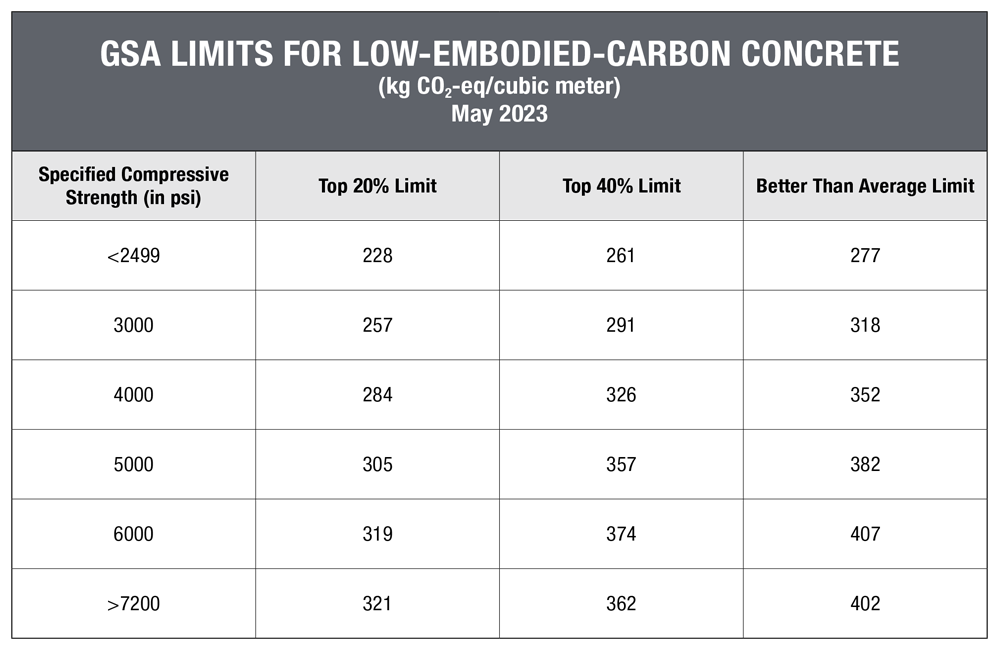

If a concrete’s GWP is equal to or less than the “Better Than Average Limit,” the mix is in the top 50% of mixes for a strength range. “Top 40% Limit” and “Top 20% Limit” show the GWP required for a mix to have an embodied-carbons content lower than 60% or 80%, respectively, of mix designs for a particular strength.

An Easy Way to Interpret This

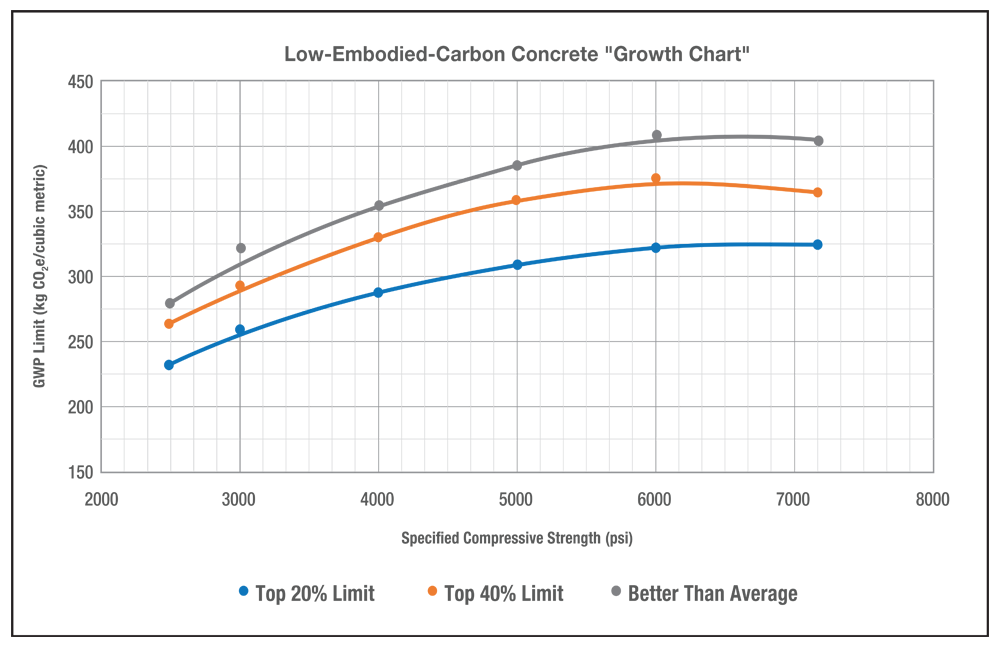

If this concept is difficult to wrap your mind around, I liken it to something from my personal life as a parent of young children. At each pediatrician visit, the doctor typically shows where the child falls on a growth chart. She might say, “Your child is in the 40th percentile for weight and 50th percentile for height.”

The GSA’s table defines the 20th, 40th and 50th percentiles for embodied carbon in a concrete mix. The chart below shows what that may look like.

How This Gets Implemented

The GSA table is like a wish list. The best-case scenario for GWP reduction is for a mix to be in the Top 20% category. If such a mix isn’t available, a Top 40% mix would be used. If neither is available, Better Than Average would be allowed. A third-party-verified Type III EPD must be submitted for the mix to verify the GWP.

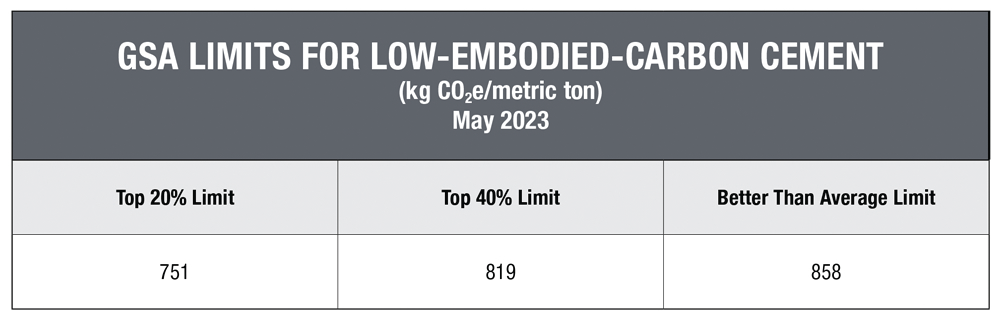

If none of the above is possible, a project team may apply the GWP limits to the cement used in the mix. Those ranges are broken into the same categories, like this:

Note that, at 673 kg CO2-eq per metric ton, Rapid Set® Cement is well within the Top 20%. This is because it is a different chemistry than portland cement, which is 922 kg CO2-eq per metric ton. LEC concrete can be made by replacing some of the portland cement with supplementary cementitious materials (SCMs), but availability and quality may be limited and blending variability could affect durability. Rapid Set® requires only water and is available nationwide.

Here’s the Wrinkle…Two, Actually

First, the industry-average GWP is based on EPDs collected from supply chain partners. That figure will change as more EPDs are collected from more sources nationwide.

Second, all this applies only to cement and concrete used in projects that are federally funded. Some states may elect not to define LEC concrete at all, making this entire discussion moot. A state may decide to require whatever numbers the federal government eventually finalizes. A state may use the federal protocol but issue its own GWP limits based on local data. Cement producers would most likely be the first supply chain partner to be required to submit an EPD, but a state could also require ready-mix suppliers and/or contractors who own volumetric mixers to as well.

California, Colorado, Hawaii, Illinois, Maine, Maryland, Massachusetts, Michigan, New Jersey, New York, Oregon and Washington are or will soon require EPDs. If you suspect your state may take a similar approach, I recommend developing an EPD sooner rather than later because the document can take months and thousands of dollars to produce.